There are nearly 1,000,000 food service establishments (FSE) in the US, and many of them have a grease trap outside the building. A grease trap is a watertight tank designed to intercept, congeal, and retain or remove fats, oils, and grease (FOG) from food-service wastewaters; it may be located inside (grease separator) or outside (grease tank or grease trap) of a facility that generates commercial food service wastewater. Today, we will be focusing on grease traps outside the building, but if you have a grease separator within your FSE, it should be maintained regularly by kitchen or management staff.

In restaurants, FOGoriginates in the kitchen or bathroom. Kitchen FOG usually comes from disposing of animal- or vegetable-based food scraps or residue down the sink and into the system. Wastewater from sources with garbage disposal devices typically contains 30 to 40 percent more FOG than those that do not use garbage disposals. Ineffective grease removal from these waste streams results in the discharge of large quantities of FOG into public sanitary sewer systems or septic systems. Solidified grease can cause stoppages downstream in the piping networks and create costly and time-consuming problems at municipal wastewater treatment plants. Grease blockages can also cause considerable unnecessary health hazards when raw sewage backs up into residences or commercial establishments. It can also plug up septic system components, particularly systems that utilize soil pores, as it coats and plugs them up. By trapping FOG and solids normally found in FSE, a grease trap is the last line of defense against potential problems downstream.

Some municipalities charge sewer line maintenance fees, and if they can trace the source of a blockage causing a sanitary sewer overflow to a particular FSE, the FSE may be liable for the cleanup cost and fines. Grease traps are a necessary component of pretreatment programs and are generally necessary in order to comply with U.S. Environmental Protection Agency (EPA) requirements for systems connected to a wastewater treatment plant. The greatest source of FOG loading comes from food service establishments that do not have a grease trap installed or from grease traps that are not properly maintained.

Gravity traps are often made out of concrete but can also be steel, fiberglass or plastic. They come in various sizes to accommodate different flow rates and are ideal for restaurants, cafeterias and other food service establishments.

How Grease Traps Work

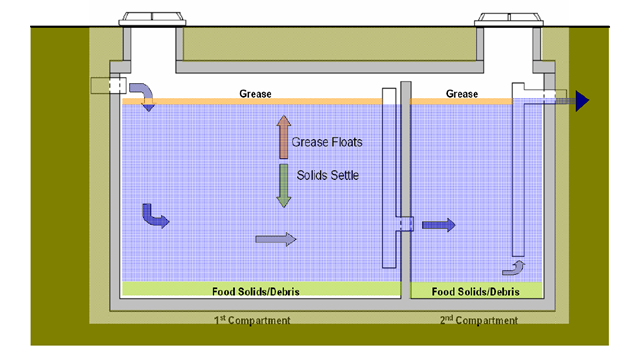

Effective grease traps are designed to slow the incoming wastewater, so the FOG floats to the top and solids settle to the bottom of the trap. If these accumulations of FOG are not routinely pumped out of the trap, the contaminants overflow the trap and contribute to downstream problems.

Grease traps work on the principle of gravity and buoyancy. When wastewater enters the trap, it cools down, causing FOG to rise to the surface due to its lower density than water. The treated wastewater, which is lower in FOG, exits the grease trap through an outlet. Solid food particles and other debris settle at the bottom of the trap. The diagram below (WERF, 2008)shows how the solids settle to the bottom, and grease floats to the top.

There are no moving or mechanical parts in gravity-type grease traps that require operation or adjustment. Thus, the passive operation of the traps is affected by the way in which they are used (flows) and the substances (how much FOG and food particles) that are allowed to enter them.

Maintenance

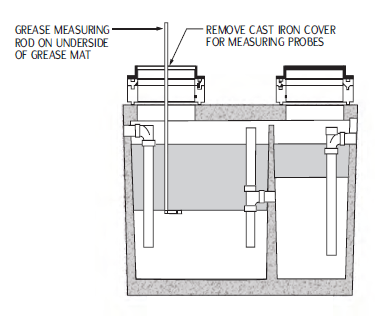

Typical recommendations and requirements for grease traps require them to be serviced when the depth/percentage of FOG reaches 25%. This can be determined from the surface as shown below (NPCA, 2025)

During a typical grease trap cleaning, the grease trap will be inspected, the accumulated waste removed, and the interior surfaces cleaned. The use of specialized tools and techniques to remove the solidified FOG and food particles is often needed to get the tank thoroughly cleaned. Additionally, the tank will be checked for signs of damage or malfunction that might require further attention.

All grease traps require maintenance to ensure an acceptable level of effluent FOG. This requires a regular schedule of pumping and inspection. When the grease trap is new, it is difficult to define the maintenance schedule, and so it is difficult to ensure compliance, but after a period of time, the correct interval can be determined. For new installations, a monthly cleaning may be required until the maintenance company can establish a predictable level of FOG accumulation for that particular facility. Thereafter, required cleanings may be extended until an optimum pumping frequency is determined. The jurisdictional authority may also require notification from either the owner or the maintenance company when a scheduled cleaning is performed (or missed) or when a contract is not renewed. Keep a maintenance log to help optimize clean frequency and reduce costs. These records should be kept on site as many jurisdictional authorities require proof that the trap has regular maintenance.

Automated monitoring systems are now available that monitor the levels of FOG in the tank. They provide an early warning to management that the grease trap is nearly full and needs pumping. In addition, the systems can minimize pumping costs by optimizing the pump-out interval. Automated systems provide documentation for the jurisdictional authority and can even be monitored off-site.

Dos and Don’ts

The first issue is that if FSE dispose of used FOG, it should be collected in the facility and recycled. This will entail contracting with a collection company and training workers on how to collect and manage these used products. RSE managers should be encouraged to train their workers to catch as much of the FOG as possible before it goes down the drain. This will not only reduce problems with their effluent but will also limit the amount of waste that will need to be managed.

Other best management practices for facilities with grease traps:

- Post “No Grease or No FOG” above sinks and near drains to minimize discharge to traps.

- Secure floor drain covers and screens to reduce the introduction of large items into drains

- Install a strainer or basket in sinks and drains to capture large food particles and solid debris

- Avoid pouring hot water or chemicals down the drain as they can dissolve grease, causing it to bypass the grease trap

- Scrape plates and utensils before washing. This can significantly reduce the amount of FOG entering the trap.

- Dry-wipe pots, pans and dishware prior to washing.

- Use a 3-sink system with separate sinks for washing, rinsing and sanitizing.

- Use dishwashing and general cleaning detergents that promote rapid oil/water separation. These detergents are formulated to release oil quickly so that the oil can rise to the water surface instead of remaining emulsified.

- Use proper concentrations of cleaners and disinfectants. Excessive amounts of either can cause FOG to become emulsified and pass through the interceptor.

- Do not use water that is hotter than necessary to clean and sanitize wash items. Use temperature settings recommended by the dishwasher manufacture. Some agencies require water temperatures be limited to 140 degrees.

- Do not use additives such as enzymes, grease solvents or emulsifiers. Most regulatory agencies prohibit their use. Enzymes and solvents temporarily emulsify grease, allowing it to pass through the trap. The grease later coagulates on the inside walls of sewer pipes, restricting flow, which could result in sewage backups and blockages.

- Do not put corrosive agents down the drain or into the grease interceptor.

- Do not use food grinders/garbage disposals. Dispose of food waste into a solid waste or compost container. Although the interceptor is designed to remove grease-laden food particles from the wastewater stream, it also increases the pump-out interval and could lead to potential odor and/or reactivity problems due to food particles breaking down biologically and releasing gases within the trap.

- Keep dry absorbents ready for any grease or oil spills.

Odors

Odor issues with outdoor grease traps can be eliminated when a properly designed grease trap is incorporated into the building’s plumbing/venting system. Most building codes require the trap to be vented back through the inlet plumbing and to a roof vent. In almost all cases, odor problems are caused by improper venting of the building’s plumbing system. This causes the gases to build up in the trap and allows them to escape, leading to odor problems. Proper building ventilation and trap design, along with gastight manhole covers and seals, will prevent odors from escaping the trap and allow them to properly escape through the roof vents. Additionally, when precast concrete gravity grease traps will be dormant for more than 30 days (schools, churches, etc.), the preferred practice is to pump and refill the trap with clean water before the long period of inactivity.

Summary

Grease traps are critical infrastructure for food service establishments. Grease trap maintenance on a regular basis is critical to protecting downstream wastewater components. Work with your service provider to determine the appropriate interval for pumping and cleaning of your trap. Follow best management practices to minimize the need for pumping and protect downstream components.